How Much Does It Cost to Heat a Warehouse

Heating A Warehouse: How Much Does It Really Cost?

Have you ever stopped to consider how much it costs to heat a warehouse? Well, we have, and the numbers are quite staggering.

Warehouse Wattage

When you have valuable materials to store through the winter months, keeping your warehouse at the proper temperature becomes an operational expense.

According to Madison Gas and Electric, "warehouses in the U.S. use an average of 7.6 kilowatt-hours (kWh) of electricity and 20,900 Btu of natural gas per square foot annually," (Madison). Even if you're only heating a 20X20 ft. warehouse, which would be incredibly small, that's still an average of 3,040 kilowatt-hours and 8,360,000 Btu of natural gas annually. Over a year, that really adds up. The real issue, however, is that it is not the building that needs to be heated. In most cases, the warehouse needs to be warm because you need to keep the materials and/or equipment inside at proper temperatures.

Tips for Preventing Heat Loss

Large buildings with high ceilings and many doors and windows are not the easiest place to keep warm air in. Additionally, many industrial facilities accept deliveries or shipments several times a day, exposing the space to outdoor conditions. Consider these four areas of your warehouse and how you can conserve energy with simple improvements.

Check for Air Leaks Around Windows

Over time, the seal around most windows will begin to wear down. Leaks often go unnoticed because many warehouses have high windows that are hard to reach.

Keep the Heat: As part of your maintenance schedule, check the air temperature of the areas around your window at least a few times a year to see if the air is unusually hot or cold. If you recognize low temps, check the insulation around the window and possibly replace or add new weatherstrips.

Circulate Heat Collecting at the Ceiling

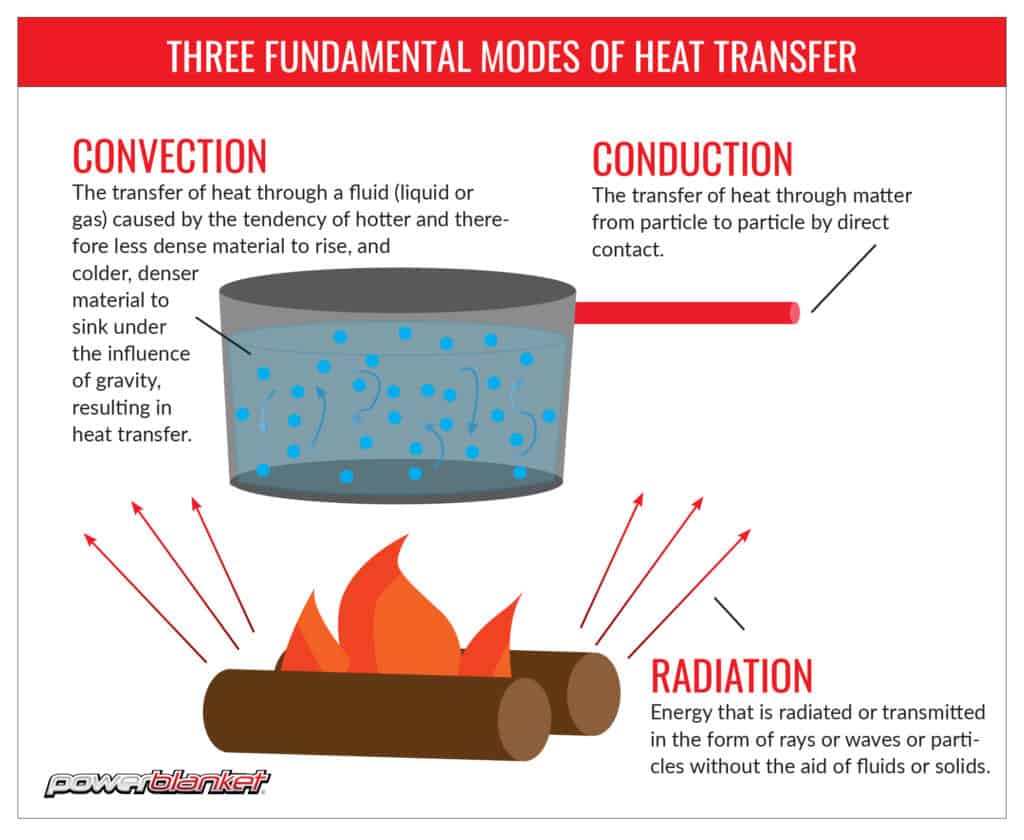

Heat rises above cold air in a building. This difference in air density can cause problems in a warehouse with high ceilings. This phenomenon is problematic because the heating system doesn't properly heat the lower areas where employees are.

Keep the Heat:Destratify the air in your space by increasing airflow. Improved airflow in your warehouse helps maintain more consistent temperatures, or thermal equalized. Circulating the air keeps those working in the warehouse warmer without cranking up the heat.

Control Your Heating

Awareness is key. You always want to have sufficient control over how much heat your building is using. You want to keep the building comfortable, but your energy bill should not destroy your bottom line.

Keep the Heat:Invest in a better method of monitoring the heating in your building. With today's technology, there are numerous ways to monitor temperatures and energy use remotely. Save money when you lower the heat when it is not necessary.

A Better Solution

An efficient building is an important part of optimizing operations. Consider this, if you could heat only the materials you are storing in your warehouse, rather than the warehouse itself, how much could you be saving on energy cost in a year? The square footage you'd need to heat would be a small fraction of your warehouse's dimensions. Is your warehouse primarily for storage? Consider turning the heat off and still protecting your valuable materials.

There is an economical solution to such a scenario. Powerblanket manufactures standard heating equipment and custom heating solutions for freeze protection and storage. Whether you're storing paint, coatings, spray foam, wax, chemicals of various kinds, DEF, propane, or anything else that may need to be stored at room temperature or above. Powerblanket covers your assets. Using radiant heating technology, Powerblanket products protect materials and equipment with even and direct heat distribution.

How Much Does It Cost to Heat a Warehouse

Source: https://www.powerblanket.com/blog/heating-warehouse-much-really-cost/